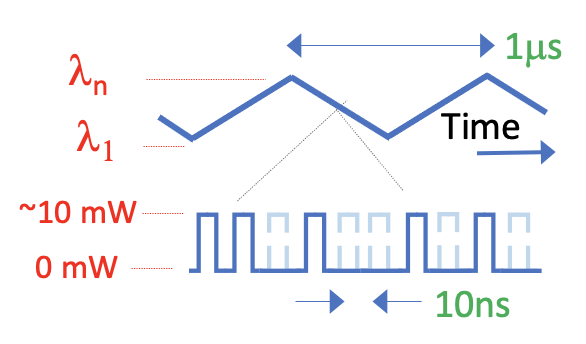

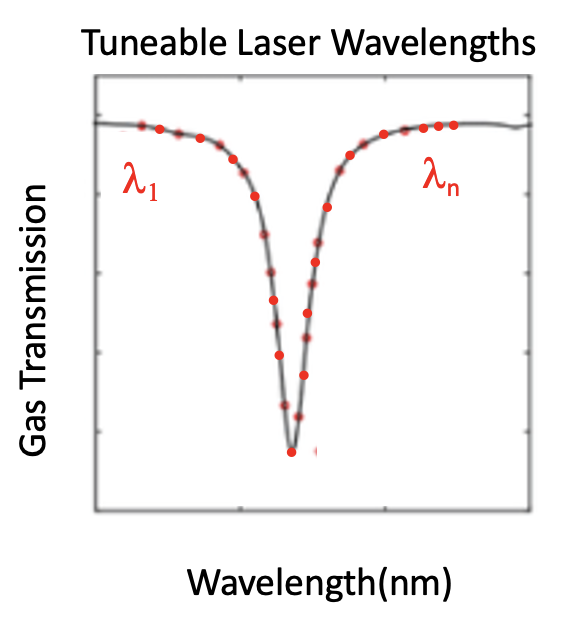

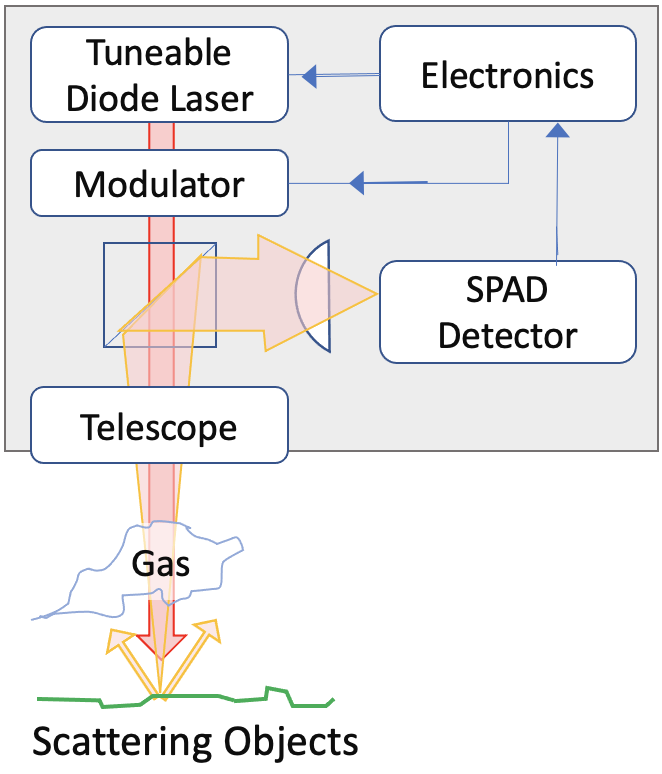

How does it work?

The lidar's laser is continuously tuned in wavelength over an absorption line of the gas

molecule of interest, in this

case methane in the near-infrared at 1651nm. The laser is simultaneously amplitude

modulated

with a random code and is

projected by the lidar transceiver out onto objects in the distance, passing through any

gas

plumes between the solid

object and the lidar. Light scattered off surfaces in the distance travels back into the

transceiver and is detected by

the SPAD.

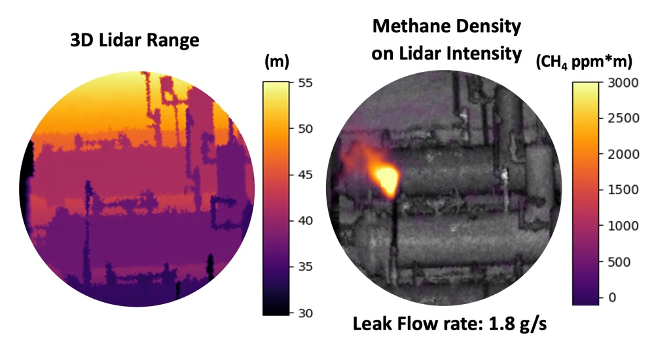

The time-correlated lidar signal gives the distance to scattering surface and using

absorption spectroscopy enabled by

the laser tuning, the gas concentration pathlength (ppm*m) is measured along each

pointing

vector of the laser as the

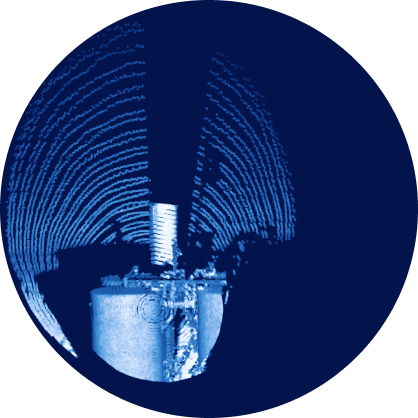

lidar scanner - a set of rotating Risley prisms - scans the beam across the lidar's

circular, two-dimensional field of view (FoV). This provides a lidar point cloud from

which lidar images (lidar

intensity

and range) and a gas density

image of any gas plume within the FoV can be produced.

Scanning the lidar's laser around a scene builds up a 3D picture (lidar point cloud) of

objects and gas showing the exact plume location, shape and size.

The total gas volume is calculated by summing up the individual gas density measurements

at

each point and then using

the lidar distance measurement to determine the physical size of the plume as seen by

the

lidar. To calculate gas

emission (flow) rate, the wind speed and direction is measured locally with an

anemometer

and this data is used to

calculate the volumetric flow of the gas plume through the FoV.

To date, QLM has produced lidars for detecting CH4 and CO2,

and we plan to add other

gas species in the near future

such as ammonia.

QLM Analytics - transforming lidar data into actionable

information

QLM's system captures environmental and lidar point cloud data that contain a wealth of

time-based, 3-dimensional and

gas plume information. This rich dataset can be mined with the customizable analytics in

the QLM Cloud solution to

support a variety of operational objectives - from early warning and remote leak

detection, to LDAR supplementation to

emissions reporting, management and compliance for ESG or RSG initiatives. QLM's unique

lidar technology not only

uncovers individual sources of fugitive emissions on a facility, but it can also be used

to produce a highly-credible,

full-site measurement of emissions with very high time resolution for regulatory

emissions compliance purposes.

To prioritize actions to address emitters, we want to know:

- What exactly is leaking (and what is not leaking!)

- How big is it?

- When did it start/end?

- Is it a vent or a leak?

- Is it expected or unexpected?

- Is it a safety issue?

- Is it caused by routine activity?

- Is it real and not from some other site or source?

- And most important of all, is it actionable - with what urgency?

Emission sources have characteristics we can measure that define their importance:

- Emission Rate & Variation

- Duration / Persistence

- Location

- Timing Patterns

QLM's analytics transform these data to prioritized actions.

QLM's technology has been thoroughly evaluated by industry and accredited third party and

academic organizations. These

include multiple test campaigns at the Colorado State University METEC (Methane

Technology Evaluation Center ) facility,

multiple tests at the TotalEnergies TADI (Total Anomaly Detection Initiative) facility

in France, and multiple tests at

the UK National Physical Laboratory (NPL).